SHIN-ETSU SUBELYN®

Fluorinated Anti-smudge Coating KY-100 Series

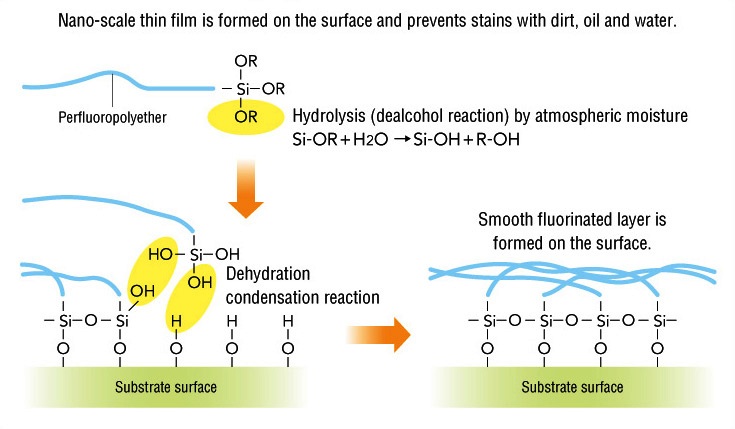

KY-100 Series are coating materials consist of organofluorine group and reactive silyl group. When very thin coatings with KY-100 Series are applied onto various substrates, excellent surface characteristics are obtained.

Features of KY-100 Series

- Anti-smudge

- A smooth fluorinated layer is formed on the surface and prevents stains with dirt.

- Removability of fingerprint

- Persistent fingerprint can be removed easily by wiping.

- Water and oil repellency

- Repels water/oil and keeps substances clean.

- Low dynamic friction

- Low friction makes wiping off easy and protects surfaces from scratches.

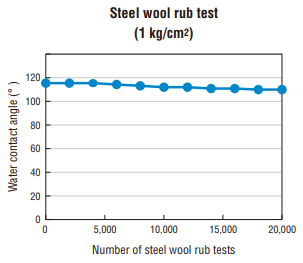

- Durability against scratches

- Protects surfaces from scratches.

- Very thin layer

- Preserves substance’s optical properties and texture.

Coating layer formation mechanism

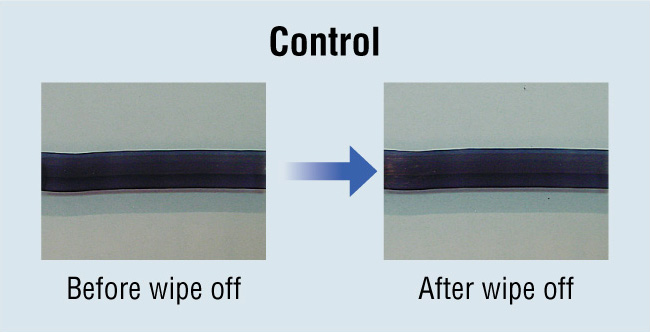

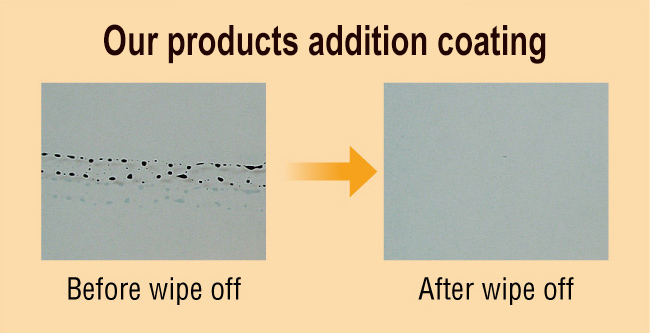

Marker ink repellency test illustrates the effect of the coating

Treatment with KY-164 provides marker ink repellency and ease of ink wiping off.

Properties

| Test item | Excellent smoothness X-71-195 |

UV resistance KY-1908 |

|

|---|---|---|---|

| Viscosity at 25ºC |

1.0 mm2/s | 2.1 mm2/s | |

| Specific gravity at 25ºC |

1.48 | 1.67 | |

| Solid content | 20wt% | ||

| Solvent | Hydrofluoroethers | ||

| Applicable thinner | Fluorinated solvents | Fluorinated solvents | |

| Contact angle |

Water | 117 deg | 116 deg |

| Oleic acid | 77 deg | 76 deg | |

| Sliding angle |

Oleic acid | 2 deg | 2 deg |

| Antifouling | Marker ink repellency |

◎ | ◎ |

| Ease of fingerprint wiping off |

◎ | ◎ | |

| Dynamic friction coefficient * 1 |

0.03 | 0.03 | |

| Steel wool rub test | ○ | ◎ | |

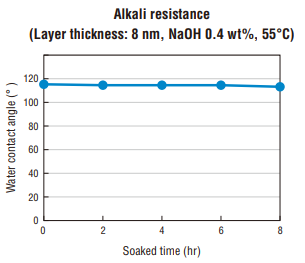

| Alkali resistance | ○ | ◎ | |

| Acid resistance | ○ | ○ | |

| Salt spray resistance | ○ | ○ | |

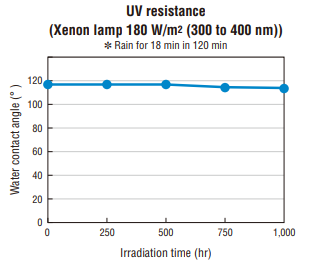

| UV resistance | △ | ○ | |

◎:Excellent ○:Good △:Fair ×:No Good

KY-1908 Durability data

Test conditions

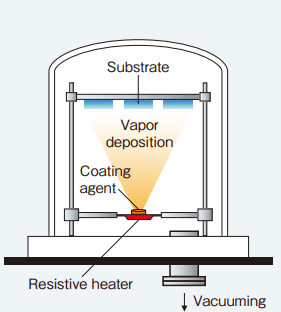

Coating process: Vacuum deposition

・Pressure < 3 x 10-3Pa

・Temperature > 350℃(Joule heating)

・Heating time 5min

Substrate: Chemically strengthened glass

Cure condition: RT /50%RH 12Hr

*1 BEMCOT unwoven cloth (Asahi Kasei, 10mm x 30mm); 100g load

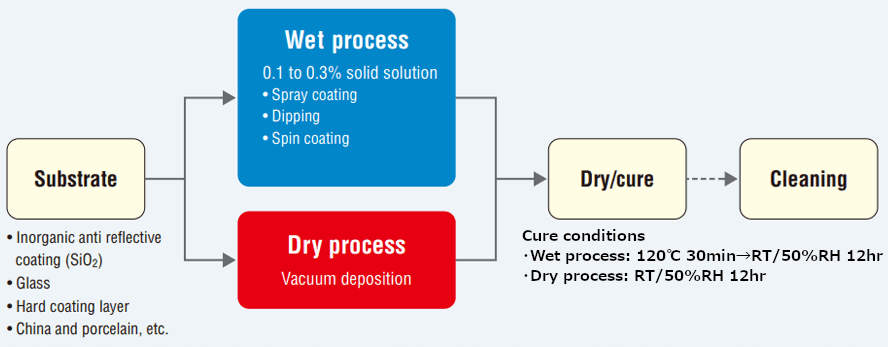

Coating process

Vacuum deposition

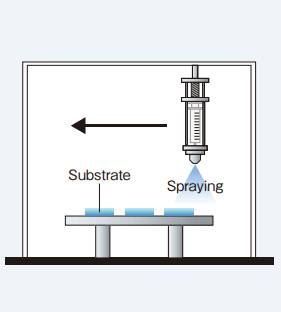

Spraying

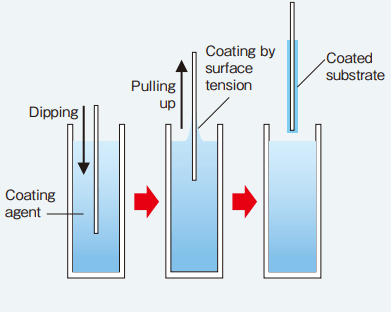

Dipping

* Please refer to the Technical Date Sheet regarding pretreatment and dilution concentration or contact us.

We can introduce some subcontract processing manufacturers.

Applications

Anti-smudge, water/oil repellency, fingerprint removability and low dynamic friction are realized by formation of a smooth fluorinated layer on various surfaces such as inorganic anti-reflective coating (SiO2), glass, and hard coating layer.

- Touch screen car stereos

- Optical lens

- Displays

- Anti-reflective film

- Hardcoated film

- China and porcelain

- Electronic devices

- Glass

- Mirror

Operationg Infomation

Strorage

- Store in cool and dark place.

- The products include highly hydrolyzable substances. They hydrolyze by water or moisture and generate ethanol. To prevent water or moisture intrusion, close bottle cap tightly after original container is opened.

For Your Safety

- To avoid skin and mucous membrane contact, use safety gloves and safety glasses.

- In case of skin contact, immediately remove the product with dry cloth, and wash exposed area with detergent.

- In case of eye contact, flush immediately with water for at least 15 minutes and get medical attention.

- Fluorinated compounds in the products may decompose at high temperature and harmful gases including hydrogen fluoride may be generated.

- When the products are treated at high temperature, adequate ventilation is required.

- Smoking cigarettes that have been exposed to the products may result in inhalation of decomposition gas. Avoid smoking at operation site and wash hands and face after operation so that cigarettes do not contact the products.

- Please refer to the relevant MSDS prior to the use of the product.

Others

- The data and information presented in this web-site may not be relied upon to represent standard values. Shin-Etsu reserves the right to change such data and information, in whole or in part, in this web-site, including product performance standards and specifications without notice.

- Users are solely responsible for making preliminary tests to determine the suitability of products for their intended use. Statements concerning possible or suggested uses made herein may not be relied upon, or be construed, as a guaranty of no patent infringement.

- The products described herein have been designed, manufactured and developed solely for general industrial use only; such products are not designed for, intended for use as, or suitable for, medical, surgical, food or other particular purposes. Users have the sole responsibility and obligation to determine the suitability of the products described herein for any application, to make preliminary tests, and to confirm the safety of such products for their use.

- Users must never use the products described herein for the purpose of implantation into the human body and/or injection into humans.

- Users are solely responsible for exporting or importing the products described herein, and complying with all applicable laws, regulations and rules relating to the use of such products. Shin-Etsu recommends checking each pertinent country’s laws, regulations and rules in advance, when exporting or importing, and before using, the products.

- Please contact Shin-Etsu before reproducing any part of this web-site. Copyright belongs to Shin-Etsu Chemical Co.,Ltd..

- The products are manufactured according to the purchase orders. For more details, please contact us.

Catalog Download

Fluorinated Anti-smudge Coating Catalog Download

Contact Us

If you have any comments or questions, please do not hesitate to contact us

Click here