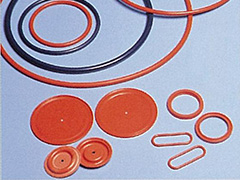

Elastomer of Liquid Injection Molding

SIFEL3000 series

SHIN-ETSU SIFEL® of Liquid Injection Molding type is designed for LIM System.

LIM System (LIMS) is a newly designed system, which includes a highly functional liquid fluoroelastomer and an injection-molding machine to precisely inject those fluids. From the set-up of raw materials to blending and molding, the entire process is automated to assure high quality products. One-component type can be used for compression molding as well.

Product Listing

Values listed are typical values and do not constitute a specification.

Two-component type

| Product Name | SIFEL3405A/B | SIFEL3505A/B | SIFEL3705A/B |

|---|---|---|---|

| Features | 40 Shore A | 50 Shore A | 70 Shore A |

| Before curing properties | |||

| Appearance | A:Black liquid B:Milky white liquid |

A:Black paste B:Milky white paste |

A:Black paste B:White paste |

| Viscosity 23ºC | A:70 Pa·s B:80 Pa·s |

A:300 Pa·s B:250 Pa·s |

A:1100 Pa·s B:1000 Pa·s |

| After curing properties | |||

| Cure Condition | Press cure 150ºC / 10 min and post cure 200ºC / 4hr | ||

| Density at 23ºC | 1.86g/cm3 | 1.86g/cm3 | 1.88g/cm3 |

| Hardness Duro A | 40 | 50 | 68 |

| Tensile Strength | 8.0 MPa | 12 MPa | 9.0 MPa |

| Elongation | 320 % | 350 % | 220 % |

| Tear Strength | 9.0kN/m | 14kN/m | 11kN/m |

| Compression Set 200ºC / 70hr (Button) |

24 % | 20 % | 20 % |

Two-componet type is designed for Liquid Injection Molding System.

One-component type

| Product Name | SIFEL3590-N | SIFEL3795 | X-71-369 | X-71-377 | |

|---|---|---|---|---|---|

| Features | 55 Shore A Liquid |

70 Shore A Highly thixotropic Type |

45 Shore A Highly thixotropic type |

85 Shore A Highly thixotropic type |

|

| Before curing properties | |||||

| Appearance | Milky white liquid | Black paste | Black paste | Gray paste | |

| Viscosity 23ºC | 50 Pa·s | 1,400 Pa·s (14,000 Poise) |

410 Pa·s | 3000 Pa·s | |

| After curing properties | |||||

| Cure Condition | Press cure 150ºC / 10 min and post cure 200ºC / 4hr | ||||

| Density at 23ºC | 1.88g/cm3 | 1.87g/cm3 | 1.88g/cm3 | 1.98g/cm3 | |

| Hardness Duro A | 55 | 70 | 45 | 85 | |

| Tensile Strength | 7.8MPa | 7.0MPa | 8.2MPa | 7.1MPa | |

| Elongation | 250 % | 170 % | 490 % | 74 % | |

| Tear Strength | 9kN/m | 9kN/m | 10kN/m | 8kN/m | |

One-component type can be used other molding method than LIMS.

Properties

Values listed are typical values and do not constitute a specification.

Cure Speed

Required Curing Condition

| Press Cure | Post Cure | |

|---|---|---|

| SIFEL(LIM) | 150ºC/<1min | 200ºC/4hr |

| Regular Fluoroelastomer | 170ºC/15min | 230ºC/24hr |

Low Temperature Flexibility

Temperature of Retraction (ASTM D1329)

| SIFEL3705 | Fluoroelastomer Regular Type |

Fluoroelastomer Low temp. Grade |

|

|---|---|---|---|

| TR-10 (ºC) | -50 | -17 | -30 |

Heat Resistance

Oil Resistance

Immersion test in automotive engine oil at 150ºC (TOYOTA SN 5W-20)

Immersion test in ATF oil (150ºC/DEXRON VI)

Solvent Resistance

Weight change in various solvents

| Solvent | Volume change % 23ºC/70hr | ||

|---|---|---|---|

| SIFEL3505 | SIFEL3705 | ||

| Hydrocarbon | |||

| Fuel C | 10 | 10 | |

| Hexane | 10 | 10 | |

| Toluene | 7 | 7 | |

| Light Oil | 1 | 1 | |

| Halogenated hydrocarbon |

Chloroform | 12 | 11 |

| Ketone | Acetone | 7 | 6 |

| MEK | 8 | 8 | |

| Ester | Ethyl Acetate | 9 | 9 |

| Alcohol | Methanol | 1 | 2 |

| Ethylene Glycol | 1 | 1 | |

| Ether | THF | 11 | 10 |

| ETBE | 15 | 14 | |

| Amine | Pyridine | 4 | 4 |

| Butylamine | 9 | 10 | |

| Amide | DMF | 2 | 2 |

Chemical Resistance

Electrical Insulation Properties

| SIFEL3705 | Fluoroelastomer | Fluorosilicone | |

|---|---|---|---|

| Volume Resistivity(ASTM D257) MΩ・m |

1X107 | 3X104 | 2X103 |

| Dielectric Strength(ASTM D149) kV/mm | 27 | 24 | 20 |

| Dielectric Constant (ASTM D150) 50 Hz | 3.2 | 11 | 6 |

| Dielectric Dissipation Factor (ASTM D150) 50Hz | 6X10-3 | 3X10-1 | 4X10-3 |

SIFEL can be used as a low-k material.

Low Moisture Permeability

| SIFEL3705 | Fluoroelastomer | Fluorosilicone | |

|---|---|---|---|

| Permeability(g/m2・24hr) | 5 | 4 | 50 |

Catalog Download

Liquid Fluoroelastomers SHIN-ETSU SIFEL Catalog Download

Contact Us

If you have any comments or questions, please do not hesitate to contact us

Click here