SHIN-ETSU SUBELYN®

Fluorinated Anti-smudge Additives

KY-1200 Series

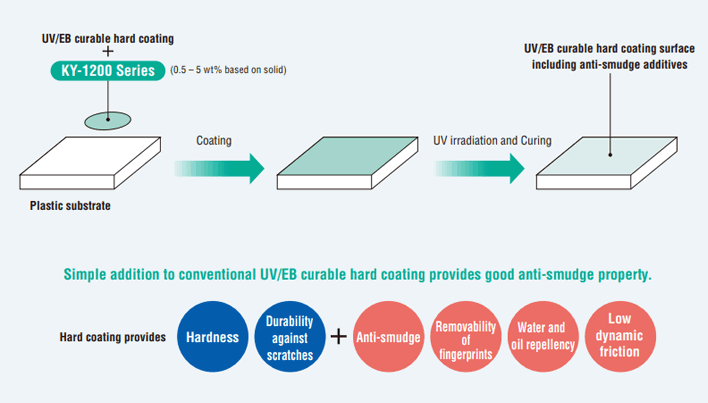

KY-1200 Series are UV/EB curable fluorinated compounds. When small amounts of KY-1200 Series are added to UV/EB curable hard coatings, surface properties such as water/oil repellency and anti-smudge effect can be added or enhanced.

Features of KY-1200 Series

- Anti-smudge

- A smooth fluorinated layer is formed on the surface and prevents stains with dirt.

- Removability of fingerprint

- Persistent fingerprint can be removed easily by wiping.

- Water and Oil repellency

- Repels water/oil and keeps substances clean.

- Low dynamic friction

- Low friction makes wiping off easy and protects surfaces from scratches.

- Durability against scratches

- Protects surfaces from scratches.

- Low refractive index

- Low refractive layer is formed

when increasing the amount of the contents.

It can be used for Low Refractive (LR) materials.

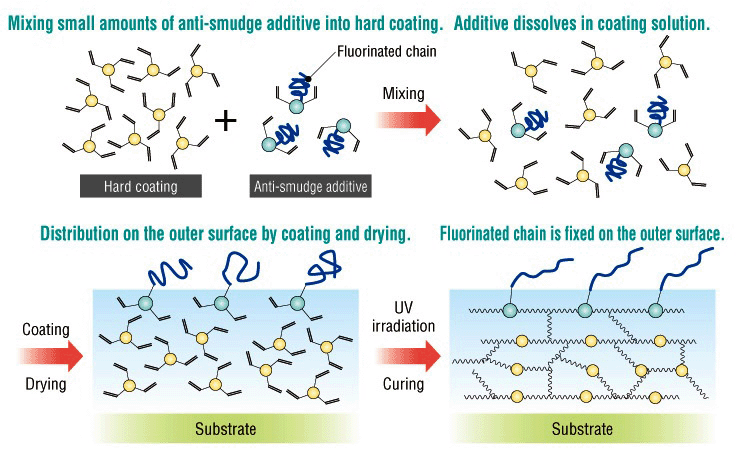

Functioning mechanism of anti-smudge additives

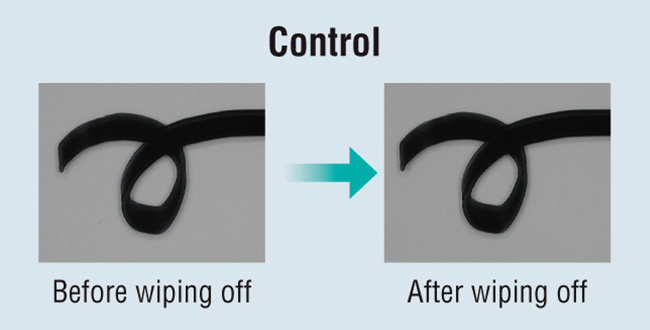

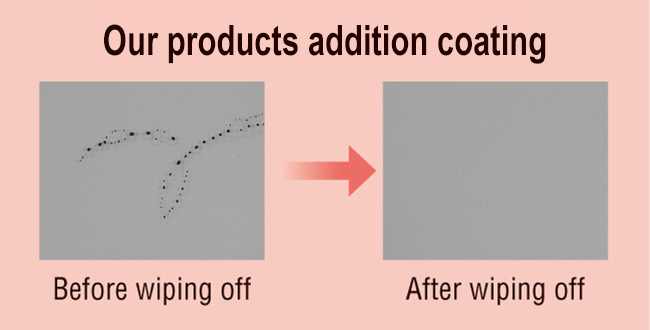

Marker ink repellency test illustrates the effect of the coating

Properties

for Acrylic hard coating

Lineup

| Item | KY-1203 | X-71-1203E | KY-1211 |

|---|---|---|---|

| Features | Standard, high waterand-oil repellency, low dynamic friction | Standard, high waterand-oil repellency, low dynamic friction | Improves compatibility with acrylic hard coatings |

| Appearance | Transparent to pale yellow | Transparent to pale yellow | Transparent to pale yellow |

| Viscosity at 25ºC | 1.2mm2/s | 0.9mm2/s | 1.0mm2/s |

| Specific gravity at 25ºC | 0.88 | 0.89 | 0.88 |

| Solid content | 20wt% | 20wt% | 20wt% |

| Solvent | MEK、MIBK | MEK | MEK |

| (Values not specified) | |||

Properties (Hard coated surface)

| Item | No addition | KY-1203 | X-71-1203E | KY-1211 |

|---|---|---|---|---|

| Water contact angle | 59° | 114° | 114° | 110° |

| Oleic acid contact angle | 22° | 73° | 73° | 70° |

| Oleic acid sliding angle | Not measurable | 3° | 3° | 4° |

| Dynamic friction coefficient | 0.60 | 0.10 | 0.10 | 0.12 |

| (Values not specified) | ||||

Application example (1wt% addition based on solid) * When adding KY-1203

- Hard coating:

- EBECRYL 40 (DAICEL-CYTEC) ……………………………100 parts

- Thinner:

- 2-propanol ……………………………………………………………142 parts

- Initiator:

- IRGACURE 184 (BASF)……………………………………………… 3 parts

- Additive:

- KY-1203…………………………………………………………………5 parts

- Substrate:

- Polycarbonate panel

- Coating:

- Spin coating: 500 rpm/10 sec + 3,000 rpm/ 20 sec

- Preliminary drying:

- 80ºC / 1min

- Curing apparatus:

- UV light (metal halide lamp) conveyor system

- Irradiation:

-

N2 atmosphere, lamp capacity 80 W/cm, accumulated power 1,600 mJ/cm2

Operating information

- Hazy mixture may depend on choice or mixing ratio of hard coating and thinner.

- By adding KY-1200 Series, curing speed of hard coating may change.

In case of insufficient cure, modify curing conditions. - The effect of the coating with KY-1200 Series may change depending on curing atmospheres even if they have the same components. We recommend to irradiate with UV light under the inert gas atmosphere for the best result.

- KY-1200 Series easily dissolves in ketone-based, ether-based, ester-based and fluorine-based solvent but doesn’t dissolve easily in hydrocarbon-based solvents and alcohol-based solvents.

- It may change compatibility and stability depending on mixing ratio of hard coating.

Please test under your conditions.

Application process

Applications

When small amount of KY-1203 is mixed with UV/EB curable compound, fluorinated chains are distributed on the outer surface, then anti-smudge, water/oil repellency, fingerprint removability and low dynamic friction are realized.

- Hardcoated film

- Anti-reflective film

- Displays

- Touch panel

- Electronic device housing

- Decorative film

Operational Infomation

Strorage

- Store in cool, dark place.

For Your Safety

- To avoid skin and mucous membrane contact, use safety gloves and safety glasses.

- In case of skin contact, immediately remove the product with dry cloth, and wash exposed area with detergent.

- In case of eye contact, flush immediately with water for at least 15 minutes and get medical attention.

- Fluorinated compounds in the products may decompose at high temperature and harmful gases including hydrogen fluoride may be generated.

- When the products are treated at high temperature, adequate ventilation is required.

- Smoking cigarettes that have been exposed to the products may result in inhalation of decomposition gas. Avoid smoking at operation site and wash hands and face after operation so that cigarettes do not contact the products.

- Please refer to the relevant MSDS prior to the use of the product.

Others

- The data and information presented in this website may not be relied upon to represent standard values. Shin-Etsu reserves the right to change such data and information, in whole or in part, in this website, including product performance standards and specifications without notice.

- Users are solely responsible for making preliminary tests to determine the suitability of products for their intended use. Statements concerning possible or suggested uses made herein may not be relied upon, or be construed, as a guaranty of no patent infringement.

- The products described herein have been designed, manufactured and developed solely for general industrial use only; such products are not designed for, intended for use as, or suitable for, medical, surgical, food or other particular purposes. Users have the sole responsibility and obligation to determine the suitability of the products described herein for any application, to make preliminary tests, and to confirm the safety of such products for their use.

- Users must never use the products described herein for the purpose of implantation into the human body and/or injection into humans.

- Users are solely responsible for exporting or importing the products described herein, and complying with all applicable laws, regulations and rules relating to the use of such products. Shin-Etsu recommends checking each pertinent country’s laws, regulations and rules in advance, when exporting or importing, and before using, the products.

- Please contact Shin-Etsu before reproducing any part of this website. Copyright belongs to Shin-Etsu Chemical Co.,Ltd..

- The products are manufactured according to the purchase orders. For more details, please contact us.

Catalog Download

Fluorinated Anti-smudge Coating Catalog Download

Contact Us

If you have any comments or questions, please do not hesitate to contact us

Click here