Liquid Fluoroelastomers

SHIN-ETSU SIFEL®

The combination of a perfluoropolyether backbone with a terminal silicone crosslinking group results in outstanding performance. We provide the most suitable product according to the applications such as liquid injection molding, adhesives and coatings, and potting gel.

Structure

SHIN-ETSU SIFEL®FFKO's combination of a perfluoropolyether backbone with a terminal silicone crosslinking group results in outstanding performance.

Adhesives and Coatings

SIFEL2000 series

SHIN-ETSU SIFEL® allows design and processing flexibility for adhesion and coating applications which will be exposed to harsh environmental conditions.

Examples are die-attachments, conformal coatings, and sealing for electronics and control devices used in severe exposure applications.

Click here

Elastomer of Liquid Injection Molding

SIFEL3000 series

SHIN-ETSU SIFEL® of Liquid Injection Molding type is designed for LIM System.

LIM System (LIMS) is a newly designed system, which includes a highly functional liquid fluoroelastomer and an injection-molding machine to precisely inject those fluids. From the set-up of raw materials to blending and molding, the entire process is automated to assure high quality products.

One-component type can be used for compression molding as well.

Click here

Potting Gel

SIFEL8000 series

SHIN-ETSU SIFEL® potting gel provides excellent low stress encapsulation performance for sensitive electronic components.

SHIN-ETSU SIFEL® potting gel has been proven to protect electronics from long term exposure to harsh environments such as fuels, solvents and chemicals.

Click here

What is SHIN-ETSU SIFEL®?

| SHIN-ETSU SIFEL® |

Fluoroelastomer | Fluorosilicone | Silicone rubber | Epoxy | |

|---|---|---|---|---|---|

| Low temperature flexibility at -50ºC | ○ | × | ○ | ○ | - |

| Heat resistance | ○ | ○ | ○ | ○ | △ |

| Resistance to polar solvent | ○ | × | × | △ | △ |

| Resistance to synthetic oil | ○ | ○ | △ | × | △ |

| Resistance to oil additives (Amine) | ○ | × | × | △ | 〇 |

| Resistance to chemicals | ○ | ○ | △ | × | 〇 |

○:Excellent △:Fair ×:No Good

Applicable for harsh environment such as exposed oils or solvents.

Keeps elasticity in the range of -50ºC~200ºC

Amine Resistance

After immersion in Butylamine

SIFEL Applications

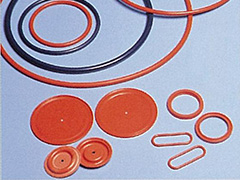

Molded rubber parts

- O-ring, Packing, Gasket, Diaphragm, Valve, Seal

- Transport vehicle

- Fuel system (Injection system, Pump, Tank, Pipes, etc.)

- Intake and exhaust system

- Powertrain (Automatic transmission system, etc.)

- Electronics parts, Electric & Electronic instruments

- Production machine of semiconductor or liquid crystal device

- Petroleum and chemical plant, Oilfield downhole equipment

- Office equipment

- Fuel cell

Adhesive, Coating, Potting

- Automotive electronics parts

- Intake and exhaust system

- Fuel system (Injection system, Pump, Tank)

- Control unit (Engine, Automatic transmission system, etc.)

- Actuator, Electric motor, Sensor

- Electronics parts, Electronic circuit and Printed board

- Production machine of semiconductor or liquid crystal device

- Printer head, Printer ink tank

- Chemical reactor

- High frequency semiconductor device

- Fuel cell

Operating Information

■Contamination Control

- Tools, devices, equipment, jigs and any other objects which will come in contact with SIFEL should be well cleaned. No moisture, oil, dirt, dust or debris is allowed.

- When SIFEL products come in contact with materials such as sulfur, phosphorus, nitrogen or amine-containing compounds or organometallic salts, curing reaction may be inhibited. Avoid any possibility of contamination.

■The materials which inhibit curing reaction

Examples inhibiting curing reaction

| Item form | Compounds that inhibit curing reaction |

|---|---|

| Rubber product (gloves etc.) | Sulfur vulcanizations, antioxidants |

| Epoxy resin, urethane resin | Phosphorus-based, amine-based, isocyanate-based curing agents |

| Condensation curing RTV silicone rubber | Tin catalysts |

| Soft PVC | Plasticizer, stabilizers |

| Engineering plastic | Flame retardants, heat-resistant improving agents, UV absorbers |

| Solder flux | Aggregation inhibitors |

To avoid curing failure:

- Remove catalyst poisons on the substrate surface: Clean the surface with ethanol, IPA, hexane, toluene etc

- Use a spatula made of plastic or metal to mix materials. When using a rubber or wooden spatula, it is necessary to comfirm whether it will inhibit curing reaction before using it.

- Use polyethylene gloves, not rubber.

- Before using machines and equipment, especially sealant, it is necessary to comfirm whether it will inhibit curing reaction.

- Clean the production line which uses epoxy resin and urethane resin because they inhibit curing reaction.

- In the case of uncured states, shorten contact time with substrates which inhibit curing reaction.

- Raise the temperature to cure (to hasten the cure rate).

■Strorage

- Seal containers tightly and keep in a cool, dark place.

Exposure to heat, sunlight, moisture or chemicals may be cause quality changes. - Some one-component types are required to be stored in a refrigerator or freezer with the appropriate temperature conditions.

■For Your Safety

- Keep containers tightly closed when not in use.

- Harmful gases may be generated when the product is heated at high temperature.

- Use only where an adequate ventilation system is available to exhaust vapor.

- Do not inhale evolved vapor.

- Avoid contact with acidic, basic, or oxidizing materials.

- To avoid eye and skin contact, use with safety glasses and safety gloves.

- Do not swallow.

- Do not smoke cigarettes which have come into contact with the product.

- Wash thoroughly after handling.

- Keep out of reach of children.

- For more information, refer to the relevant MSDS.

- The data and information presented in this catalog may not be relied upon to represent standard values. Shin-Etsu reserves the right to change such data and information, in whole or in part, in this catalog, including product performance standards and specifications without notice.

- Users are solely responsible for making preliminary tests to determine the suitability of products for their intended use. Statements concerning possible or suggested uses made herein may not be relied upon, or be construed, as a guaranty of no patent infringement.

- The SIFEL products described herein have been designed, manufactured and developed solely for general industrial use only; such SIFEL products are not designed for, intended for use as, or suitable for, medical, surgical, food or other particular purposes. Users have the sole responsibility and obligation to determine the suitability of the SIFEL products described herein for any application, to make preliminary tests, and to confirm the safety of such products for their use.

- Users must never use the SIFEL products described herein for the purpose of implantation into the human body and/or injection into humans.

- Users are solely responsible for exporting or importing the SIFEL products described herein, and complying with all applicable laws, regulations, and rules relating to the use of such products. Shin-Etsu recommends checking each pertinent country's laws, regulations, and rules in advance, when exporting or importing, and before using, the products.

FAQ

- How is SIFEL unique?

- SIFEL can be applied as an adhesive, potting and coating as well as a product for molding. This is because SIFEL is flowable liquid material in comparison to conventional fluororubber which is a solid compound. After simply curing by heat, SIFEL will become a high-performance elastomer with a high level of chemical resistance and low temperature.

- How is SIFEL cured?

- SIFEL cures at 150ºC(302F) in general but curing time differs depending on the type of product. Typical curing time is 1 hour for adhesive, potting and coating, and only one minute for LIMS grade.

- What is LIMS?

- LIMS stands for Liquid Injection Molding System. LIMS is not only efficient for mass production but will also mold precisely and consistently due to its liquid material.

- How well does SIFEL adhere to substrate?

- SIFEL 2000 series is developed for self-priming to metals, plastics, ceramics, etc. Other SIFEL series are also utilized for adhesive applications.

- Does SIFEL contain any solvents?

- No. SIFEL does not contain any kind of solvents. SIFEL is a natural liquid type without any solvent and can be provided in a wide range of viscosities. Diluted SIFEL may be available upon request.

- What is the maximum heat resistance?

- Heat resistance of SIFEL is good. Physical properties do not change even if heated at 200ºC(400F) for an extended period of time.

- What is the minimum temperature that SIFEL can withstand?

- SIFEL keeps its elasticity even at -50ºC(-58F) which is much lower than conventional fluororubbers.

- What are the current applications for SIFEL?

- SIFEL is popular in the automotive industry as well as many other industries where oil, gas, fluid, and chemical resistances with low and high temperatures are required. SIFEL adhesives, coatings, and gel are used in sealing, potting, and coating of electronic parts. In molding versions, O-rings and diaphragms made from SIFEL are the most common applications.

- What are the electric properties of SIFEL?

- Volume resistivity of SIFEL is 103GΩ·m, BDV is 30KV/mm. The most unique electric feature of SIFEL is the low dielectric constant at high frequencies; εis 2.2 at GHz.

- What is the thermal conductivity?

- Typical conductivity of SIFEL is 0.1W/m·K.

- What is the moisture permeability of SIFEL?

- It is very low, 1/20 of silicone rubber.

- What is the level of ionic impurities?

- SIFEL is very pure. Any ionic ingredients(Na+,K+,NH4+,F-,Cl-) are contained below 1 ppm.

- Is SIFEL resistant to ozone?

- No changes were observed under exposure to 100 ppm ozone at 40ºC(104F).

- What is the shrinkage rate of cured SIFEL?

- It is approximately 3% when it is molded at 150ºC(302F).

- What is the curing mechanism of SIFEL?

- SIFEL reacts under an additional curing system with the existence of platinum catalyst. This system proceeds at high yields and does not produce any by-product.

- What are the handling precautions?

- When SIFEL products are exposed to sulfur, phosphorus, nitrogen or amine-containing compounds, organometallic salts, etc., curing may be inhibited under the catalyst poison phenomenon. Avoid any type of contamination. Operation in a clean environment is required.

- How should SIFEL be stored?

- Seal containers tightly and keep in a cool, dark place. Exposure to heat, sunlight, moisture or chemicals may cause quality changes. One-component types are required to be stored in a refrigerator or freezer.