Adhesives and Coatings

SIFEL2000 series

SHIN-ETSU SIFEL® allows design and processing flexibility for adhesion and coating applications which will be exposed to harsh environmental conditions.

Examples are die-attachments, conformal coatings, and sealing for electronics and control devices used in severe exposure applications.

Product Listing

Standard Type (heat curing)

Values listed are typical values and do not constitute a specification.

| Product Name | SIFEL2618 | SIFEL2610 | SIFEL2617 | SIFEL2662 | SIFEL2614 | SIFEL2661 | SIFEL2670 | SIFEL2680 |

|---|---|---|---|---|---|---|---|---|

| Features | Liquid, Lower viscosity | Liquid | Liquid | Viscous liquid | Liquid, Improved adhesion to PPS | Viscous Liquid, Improved adhesion to PPS | Viscous liquid Improves adhesion to PPS | Viscous liquid Improves adhesion to PPS |

| Before curing properties | ||||||||

| Appearance | Milky white liquid | Milky white liquid | Milky white liquid | Milky white liquid | Milky white liquid | Milky white liquid | Milky white paste | Milky white paste |

| Viscosity 23ºC | 2.8Pa·s | 6.0Pa·s | 25Pa·s | 230Pa·s | 20Pa·s | 120Pa·s | 680Pa·s | 2,100Pa·s |

| After curing properties (150ºC, 1hr) | ||||||||

| Density 23ºC | 1.77g/cm3 | 1.77g/cm3 | 1.85g/cm3 | 1.86g/cm3 | 1.85g/cm3 | 1.86g/cm3 | 1.86g/cm3 | 1.86g/cm3 |

| Hardness(Duro A) | 34 | 35 | 28 | 38 | 25 | 30 | 44 | 45 |

| Tensile Strength | 0.6MPa |

0.8MPa |

0.9MPa |

2.5MPa |

1.1MPa |

1.6MPa |

2.7MPa |

3.2MPa |

| Elongation | 100% | 110% | 180% | 230% | 240% | 270% | 230% | 240% |

| Lap shear Strength Aluminum/Aluminum [bond line] ※1 |

3.0MPa [0.08mm] |

3.0MPa [0.08mm] |

3.2MPa [0.08mm] |

1.8MPa [1mm] |

1.3MPa [1mm] |

2.0MPa [1mm] |

2.5MPa [1mm] |

2.2MPa [1mm] |

| Lap shear Strength PPS/PPS [bond line] |

- | - | - | - | 1.5MPa (15kgf/cm2) [1mm] |

1.8MPa (18kgf/cm2) [1mm] |

1.9MPa (20kgf/cm2) [1mm] |

2.0MPa (20kgf/cm2) [1mm] |

※1 Lap shear Strength differs according to the adhesion thickness.

Low-temperature curing series

| Product name | X-71-6046 | X-71-6207 A/B | X-71-6144 A/B | ||

|---|---|---|---|---|---|

| Features | One-component Type | Two-component Type | |||

| Before curing properties | |||||

| Appearance | Milky white liquid | Milky white liquid | Milky white liquid | Black liquid | Milky white liquid |

| Viscosity 23ºC | 280Pa·s | A: 25Pa·s | B: 34Pa·s | A: 54Pa·s | B: 50Pa·s |

| After curing properties | |||||

| Cure Condition | 100ºC/2hr | 80ºC/1hr | 23ºC/24hr | ||

| Density 23ºC | 1.86g/cm3 | 1.85g/cm3 | 1.86g/cm3 | ||

| Hardness(Duro A) | 40 | 13 | 34 | ||

| Tensile Strength | 3.2MPa | 1.8MPa | 3.8MPa | ||

| Elongation | 280% | 390% | 620% | ||

| Lap shear Strength [bond line] |

1.2MPa (Prebaked PBT) [1mm] |

1.5MPa (Aluminum) [1mm] |

0.7MPa (Cohesion) (Aluminum) [0.08mm] |

||

Curing temperature dependence of lap shear strength

| Substrate | Product name | X-71-6046 | X-71-6207A/B | ||

|---|---|---|---|---|---|

| Curing temperature |

Standard (100ºC) | Low temperature(80ºC) | Standard (80ºC) | Low temperature (60ºC) | |

| Stainless steel | 1.8MPa (Curing time:2hr) |

1.4MPa (Curing time:8hr) |

1.5MPa (Curing time:1hr) |

0.8MPa (Curing time:4hr) |

|

| Aluminum | - | - | 1.5MPa (Curing time:1hr) |

0.9MPa (Curing time:4hr) |

|

| PBT | 1.2MPa (Curing time:2hr) |

1.1MPa (Curing time:8hr) |

1.7MPa (Curing time:1hr) |

0.5MPa (Curing time:4hr) |

|

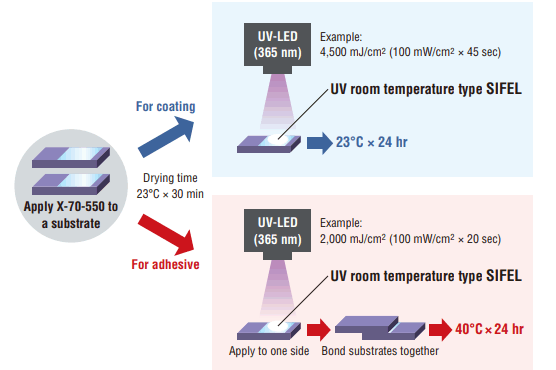

UV Room temperature type

| Product Name | X-71-6259 | |

|---|---|---|

| Features | UV Room temperature type Viscous liquid |

|

| Recommended Curing conditions | Integrated light intensity:9,000mJ/cm2 (Wavelength:365nm) |

|

| Before curing properties | ||

| Appearance*1 | Milky white liquid | |

| Viscosity 23ºC | 67Pa·s | |

| After curing properties* | ||

| Cure Condition | 23ºC/24hr. | |

| Density 23ºC | 1.85g/cm3 | |

| Hardness(Duro A) | 39 | |

| Tensile Strength | 1.6MPa | |

| Elongation | 160% | |

| Lap shear strength*2 (ASTM D1002) PPS/PPS [bond line] |

3.1MPa (using primer) [0.08mm] |

|

※activation with UV(9,000mJ/cm2), 24hr. at 23ºC(Not specified values)

*1 Promote curing by heating.

*2 Primer mentioned below is necessary for firm adhesion.

| X-70-550 (Primer) |

Viscosity: 0.61mm2/s(25ºC) Density: 0.71g/cm3(25ºC) Appearance: Slightly translucent liquid, yellow |

|---|

<<Processing>>

Data (X-71-6215)

Properties

Values listed are typical values and do not constitute a specification.

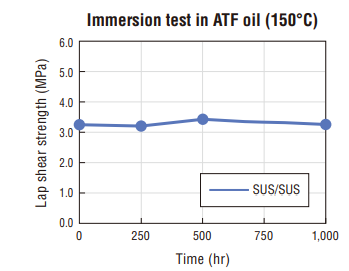

Adhesion Durability

Lap shear Strength, SIFEL2617, aluminum/aluminum, [bond line: 0.08mm]

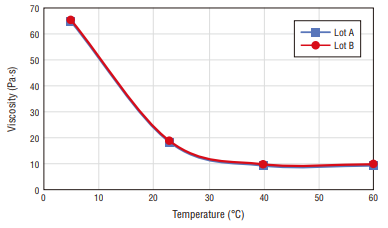

Before curing temperature/viscosity dependency

Before curing temperature/viscosity dependency, SIFEL2614

Solvent Resistance

Chemical Resistance

Self Priming Adhesion

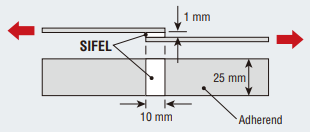

Testing the lap shear strength

SIFEL is applied as shown in the figure.

After curing, shear adhesion is measured using a tension tester.

Curing conditions: addition cure type 150ºC for 1 hr

SIFEL thickness (bond line): 1 mm (low viscous type 0.08 mm)

Adhesive surface: 10 × 25 mm2

Tensile speed: 50 mm/min

Electrical Insulation Properties

| SIFEL2617 | Fluorosilicone | |

|---|---|---|

| Volume Resistivity MΩ・m | 1X107 | 1X103 |

| Dielectric Strength kV/mm | 30 | 20 |

| Dielectric Constant 50 Hz | 3.0 | 6 |

| Dielectric Dissipation Factor 50Hz | 4X10-3 | 2X10-2 |

Low Moisture Permeability

| (40ºC/90%RH) | ASTM E96 | |

| SIFEL2617 | Fluorosilicone | |

|---|---|---|

| Permeability (g/m2・24hr) | 5 | 50 |

High Purity

| Ion species | |

|---|---|

| Na+, K+, NH4+, F-, Cl-, Br-, NO3-, SO42- |

Less than 1ppm for each species listed |

Catalog Download

Liquid Fluoroelastomers SHIN-ETSU SIFEL Catalog Download

Contact Us

If you have any comments or questions, please do not hesitate to contact us

Click here