Potting Gel

SIFEL8000 series

SHIN-ETSU SIFEL® potting gel provides excellent low stress encapsulation performance for sensitive electronic components.

SHIN-ETSU SIFEL® potting gel has been proven to protect electronics from long term exposure to harsh environments such as fuels, solvents and chemicals.

Product Listing

Standard Type (heat/room temperature curing type)

Values listed are typical values and do not constitute a specification.

| Product Name | SIFEL8070A/B | SIFEL8370A/B | SIFEL8470 | SIFEL8570A/B |

|---|---|---|---|---|

| Features | Two-component Heat cure Better low temperature flexibility |

Two-component Heat cure |

One-component Heat cure |

Two-component Room temperature cure |

| Before curing properties | ||||

| Appearance | Slightly translucent liquid, Pale yellow | Slightly translucent liquid, Pale yellow | Slightly translucent liquid, Pale yellow | Slightly translucent liquid, Pale yellow |

| Viscosity at 23ºC | A: 2.0Pa·s | A: 3.4Pa·s | 3.2Pa·s | A: 3.2 Pa·s |

| B: 2.5Pa·s | B: 2.9Pa·s | B: 3.0Pa·s | ||

| Density at 25ºC | A: 1.85g/cm3 | A: 1.86g/cm3 | 1.84g/cm3 | A: 1.86g/cm3 |

| B: 1.79g/cm3 | B: 1.83g/cm3 | B: 1.82g/cm3 | ||

| Pot life | ≧8hr | ≧24hr | - | 3hr |

| After curing properties | ||||

| Cure Condition | 120ºC/1hr | 120ºC/1hr | 150ºC/1hr | 23ºC/24hr |

| Hardness, Penetration | 70 | 70 | 70 | 70 |

Penetration measuring method

UV Room temperature type

| Product Name | X-71-8195 |

|---|---|

| Features | UV Room temperature type |

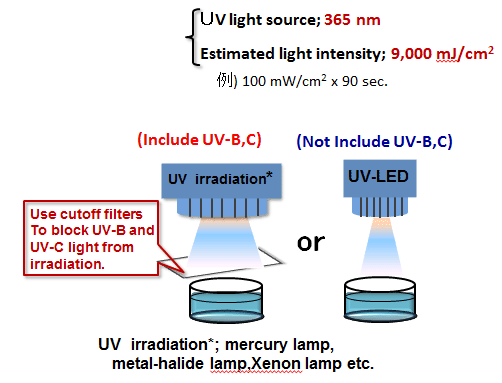

| Recommended Curing conditions | Estimated light intensity:9,000mJ/cm2 (UV light source:365nm) |

| Before curing properties | |

| Appearance | pale yellow |

| Viscosity 23ºC | 2.54 Pa·s |

| Density 25ºC | 1.86g/cm3 |

| After curing properties* | |

| Hardness, Penetration | 50 |

| glass transition temperature; Tg | -60ºC |

※activation with UV(9,000mJ/cm2), 120min at 23ºC(Not specified values)

<<Processing>>

Other products

| Hardness, Penetration around 15 |

Hardness, Penetration 35 |

Hardness, Penetration 50 |

Hardness, Penetration over 70 |

|

|---|---|---|---|---|

| One-component | ☆ | SIFEL8435 | ☆ | ☆ |

| Two-component | X-71-8015A/B | SIFE8035A | ☆ | X-71-8085A/B |

| UV Room temperature type | ☆ | ☆ | X-71-8161 | ☆ |

☆Please contact us.

Properties

Values listed are typical values and do not constitute a specification.

Solvent Resistance

Weight change in various solvents

| Solvent | Weight change % 25ºC-7days | ||

|---|---|---|---|

| SIFEL8070 | SIFEL8370 | ||

| Hydrocarbon | Fuel C | 3.7 | 3.1 |

| Toluene | 2.7 | 2.2 | |

| Light oil | 0.4 | 0.4 | |

| Halogenated hydrocarbon | Chloroform | 9.6 | 7.9 |

| Ketone | Acetone | 2.5 | 2.0 |

| MEK | 2.9 | 2.3 | |

| Ester | Ethyl acetate | 4.1 | 3.3 |

| Alcohol | Methanol | 0.3 | 0.4 |

| Ethanol | 0.4 | 0.3 | |

| Ether | ETBE | 5.6 | 4.6 |

| MTBE | 7.4 | 6.1 | |

Heat Resistance

Chemical Resistance

Low Temperature Flexibility

* Please contact us about materials that keep flexibility at lower temperature.

Oil Resistance

Low Hygroscopicity

Electrical Insulation Properties

| SIFEL8370A/B | Fluorosilicone Gel | |

|---|---|---|

| Volume Resistivity(MΩ・cm) | 2X106 | 7X103 |

| Dielectric Constant (50Hz) | 2.8 | 7.0 |

| Dielectric Dissipation Factor (50Hz) | 2X10-3 | 5X10-2 |

Low Moisture Permeability

| SIFEL8370 | Fluorosilicone Gel | |

|---|---|---|

| Permeability (g/m2・24hr) | 7 | 90 |

High Purity

| Ion species | |

|---|---|

| Na+, K+, NH4+, F-, Cl-, Br-, NO3-, SO42- |

Less than 1ppm for each species listed |

Catalog Download

Liquid Fluoroelastomers SHIN-ETSU SIFEL Catalog Download

Contact Us

If you have any comments or questions, please do not hesitate to contact us

Click here